We produce a broad and versatile array of small parts cost-effectively. We specialize in close tolerance, small, thin metal parts, and we utilize tooling designed that minimize scrap. With the high cost of metals, especially precious metals, this can result in considerable part cost savings.

Learn more about our broad array of capabilities below…

Manufacturing Consultation

We strongly encourage our customers to collaborate with us in the early stages of part development. Once we understand the fit, form, and function of your part, we advise on process and tolerancing that optimizes your part. This time and cost saving step is vitally important to manufacturing parts that are reliable, of the highest quality, and provide the most efficient solution.

Prototyping and Low Volume Production (Short Run)

Whether you need prototypes, occasional short runs, or scaling options prior to high volume production, this department is purposed for it. We work out the kinks in mechanics and fine tune our tooling to give our customer the peace of mind knowing that we will deliver results. We think ahead when designing low volume tooling by understanding how the part would be manufactured on the fourslide machine and mimicking our production tooling. At Northwest Fourslide, prototype parts closely emulate production parts.

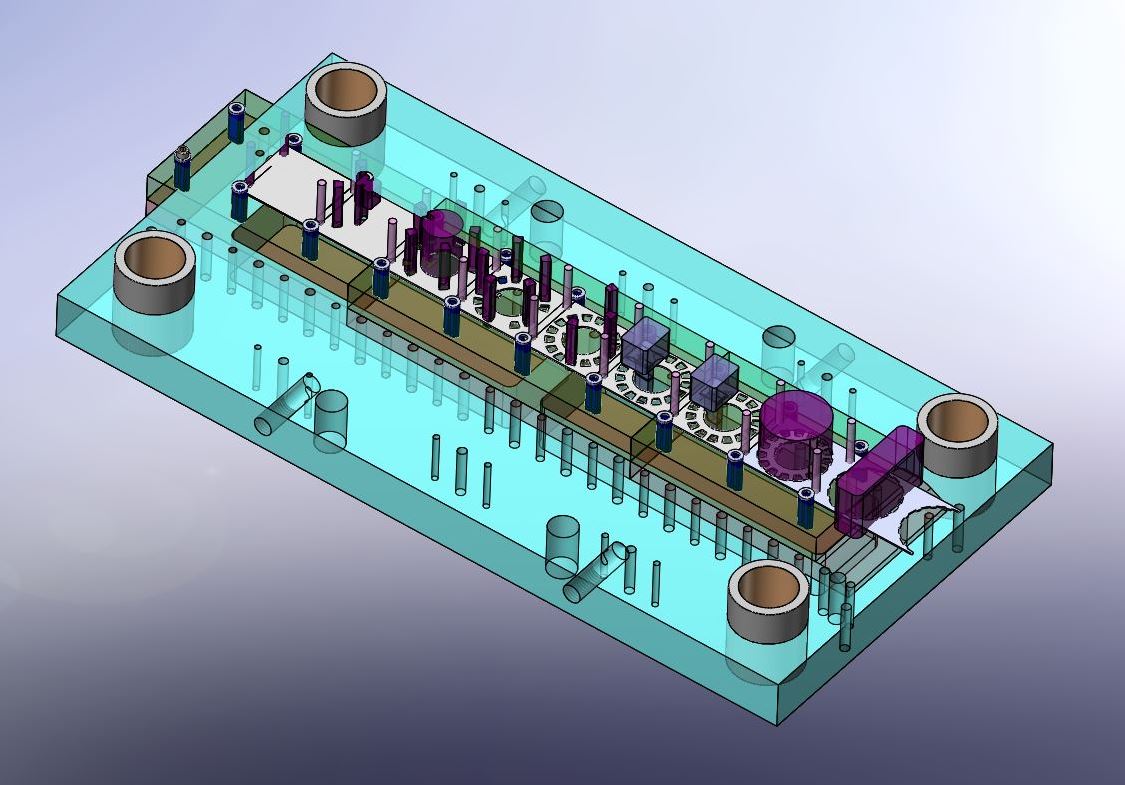

Fourslide Tooling and Production

Whether tens of thousands or millions, we will support your needs with the quality you expect. We only produce class-A tooling for our customers. Tools are maintained for the life of your part. Visit our About Us page to see video of the fourslide in action.

Value-Added Manufacturing

Available upon request on part by part basis. Northwest Fourslide has produced parts where additional processes were added.

- Automated install of plastic rollers

- Creation of a point on wireforms

- Welding of parts

- Assembly

- Reel to reel production

- Tape and Reel packaging

Wire EDM

We produce tools and part blanks with only .0001″ tolerance. We have the latest technology in wire EDMs to meet customer requirements and take on the most challenging jobs.

- XYZ stroke 15.75 X 11.80 X 8.60 table size

- Wire diameter .004 – .012

- .004 wire for .002 inside radi

- Taper angle 15 degrees at 8.0”

Post Processing

In-house capabilities:

Heat Treat

- Inert Gas Ovens

- Heat treat of Beryllium Copper parts

- Stress Relief of Stainless Steel

Deburr

- Deburr capabilities specific to part

- Custom selection between five agitation options and numerous media choices

- Polishing available

Parts Washing

Passivation (with Ultrasonics)

- Citric 1-5 per ASTM A967

- Method 2 per AMS 2700

Wire-EDM